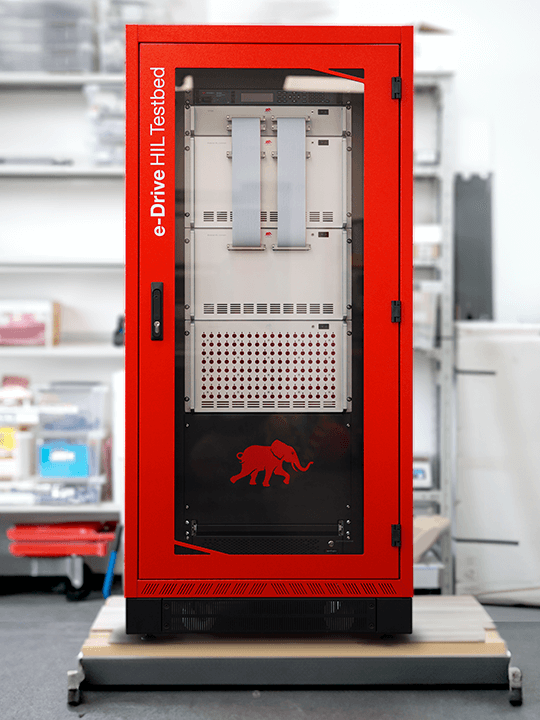

e-Drive HIL Testbed

Typhoon’s e-Drive HIL Testbed offers the complete validation solution of your e-Drive ECU according to requirements outlined in ISO26262.

Experience Seamless Integration with Our Turnkey e-Drive Testbed

With a fully vertically integrated approach, this test bench is delivered turnkey for your specific DUT. It features high-fidelity machine and inverter models parameterized according to your FEM software and lab data, and supports all required signal types and ranges for HIL level testing. Additionally, our integrated software-controlled Fault Insertion allows you to conduct both manual and automated testing, and control all ancillary bench equipment from a single software GUI.

Our e-drive testbed allow you to:

- Validate power electronics controllers using high-fidelity, ready-to-use models of power converters.

- Effortlessly interface you controller using production-grade connectors.

- Create various test scenarios in the simulation and emulate fault conditions in the hardware for accuracy testing.

- Reduce testing costs and save time by improving the speed and reliability using TyphoonTest automation.

Discover the essential components to construct your testbed.

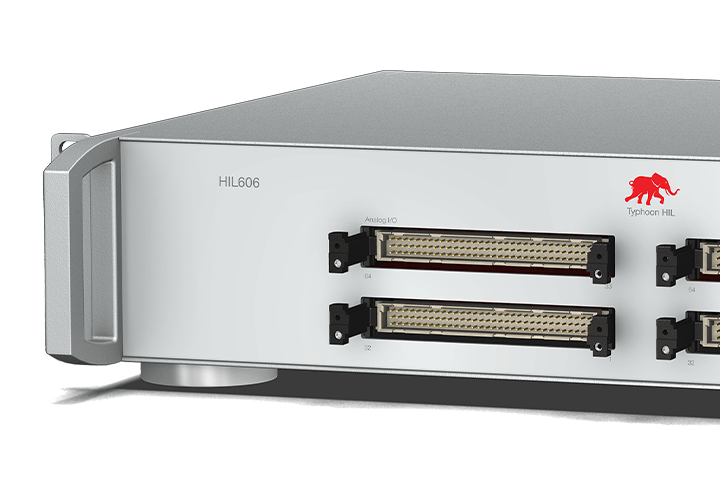

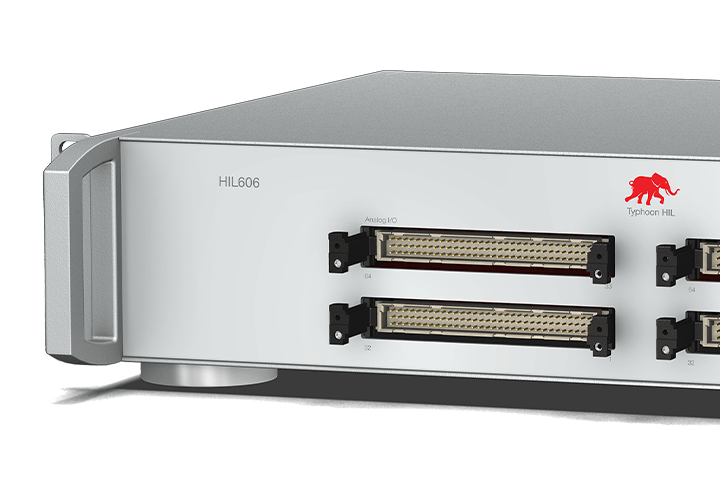

HIL606

Meet the heart of the e-Drive HIL Testbed: the HIL606 simulator. Capable of simulating models with time steps as low as 200 ns, it supports up to quad-motor systems per device. The HIL606 offers analog and digital I/O, along with robust interfaces for standard automotive communication protocols.

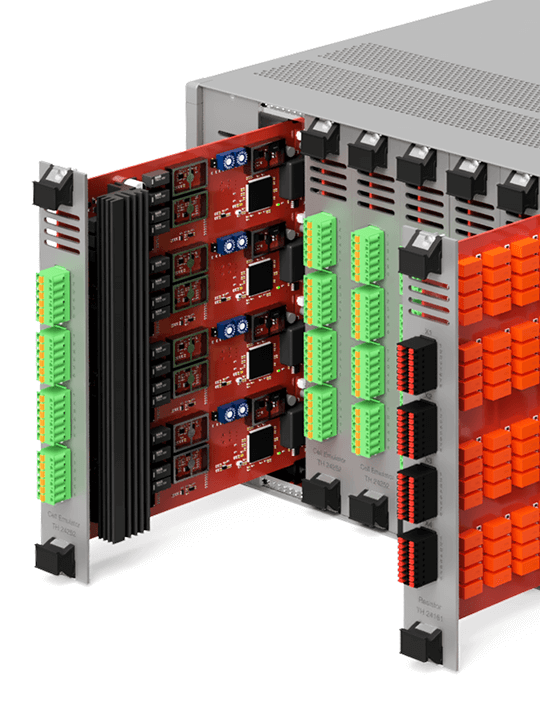

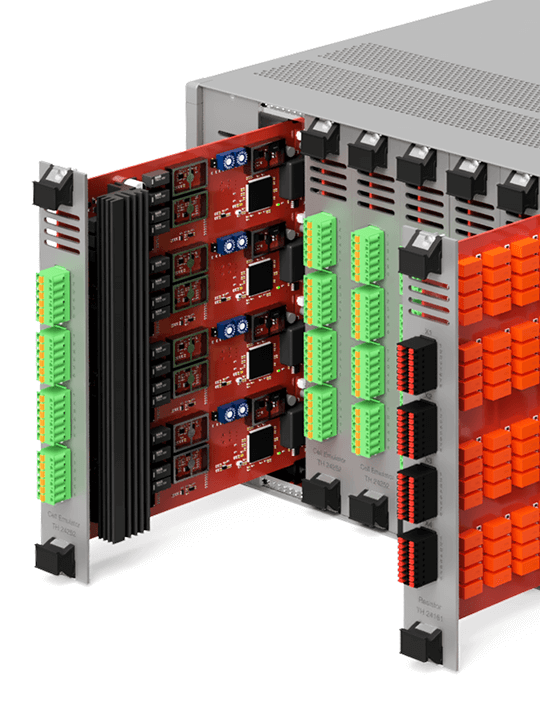

HIL Connect

To create a testing environment for the ECU that closely mimics real-world conditions, a signals value may exceed the ±10 V range of the HIL device in which the ECU converts to temperatures. The e-Drive configuration for HIL Connect supports various signal types and ranges involved in e-Drive and charging. It also features an interface for 24V gate drive signals.

The e-Drive HIL Connect is equipped with:

- Analog Input Card: 16ch, ±24V

- Analog Output Card: 32ch, ±24V

- Digital Input Card: 32ch, universal 3.3 V to 24 V

- Digital Output Card: 32ch, 3.3 V, 5 V, 15 V, or 24 V

- Resistor Emulator Card: 8ch, 0-655kOhm

- Relay DO Card: 32ch, 100V 5A rated

- ACE Card: CAN, CAN-FD, LIN, SPI, FlexRay

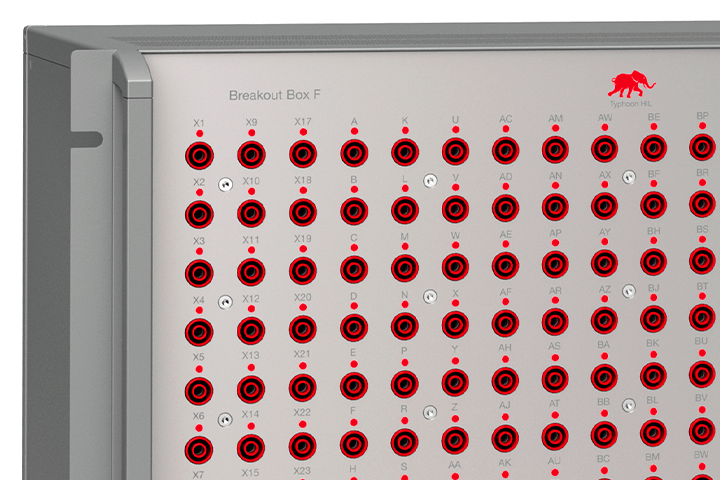

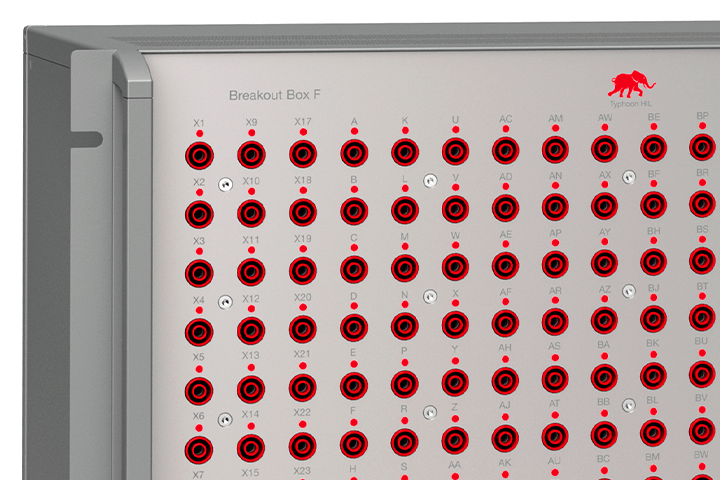

Breakout Box F

The Breakout Box F is your gateway to accurately representing real-world faults. With specialized hardware and front panel sockets, it allows you to simulate open circuits, short circuits to battery and ground, and short circuits between terminals. Each of the 150 signals can be shorted to one of three different potentials, bringing a new level of precision to your fault testing.

Ancillary Bench Equipment

Our e-Drive HIL Testbed is a complete, turnkey solution, housed in a Typhoon Red 33/37U rack and equipped with everything you need:

- Terminal Block Wiring System: Shielded and protected cabling for noise-sensitive signals.

- Main Power Control Unit (MPCU): Operates the bench power and provides safety for the operator. Equipped with automatic disconnect capability and an emergency switch.

- DC PSU: Multi-Channel DC Power Supply used for battery (KL15, KL30) simulation, board power.

- Bench PC: 2U Rack Mounted Industrial PC for remote bench operation.